Hey Again! Let’s talk about having some fun while saving some money — lots of money, as a matter of fact!

Hey Again! Let’s talk about having some fun while saving some money — lots of money, as a matter of fact!

In the world of green this and green that, with electric vehicles, lawn equipment, and scooters, we want to do our part to make the planet a better place.

Less reagents, less waste seemed like a good place to start. So, we set out on a quest to do just that. Around the time the world fell off the rails due to COVID, we were busy working on a peristaltic pump tubing harness for our QuickTrace® M-7600 that uses smaller inside diameter tubing to produce results that all our customers have come to know and love as the industry standard, but with, wait for it … less waste and a much smaller chemical footprint. Now what could be more fun than saving money for the boss!

Advantages to our QuickTrace® M-7600 continuous flow mercury analyzer with our gas liquid separation (GLS); 4 channel, 12 roller peristaltic pump; and precise mass flow controller for gas flow:

- Ultra-trace Method Detection Limit

- Sample is not consumed, allowing repeats and validation checks

- Dial-in the systems for high-performance or ultra-trace analysis

- Wide dynamic analytical ranges (not possible with one-size-fits-all direct purge approach)

- Difficult samples will not foam into the Hg gas stream, causing optical failures

- Over-range protection

- Liquid uptake from ≥ 0.5 mL (5 second sample) to max RPM (~ 15 mL/min; M-7600 w/standard tubing harness)

The system’s broad linear ranges: greater than 4 orders of magnitude for the system; for example, it is very common for a calibration of 1 ng/L to 10,000 ng/L to present at greater than 0.999 R2.

The dynamic ranges for the QuickTrace® M-7600 with the original tubing harness is < 0.5 ng/L to ~ 500 µg/L. With our “new” green chemistry peristaltic pump tubing harness, we maintained the lower portion and expanded the upper range, < 0.7 ng/L to ~ 700 µg/L.

AN1905 Reduce Reagent & Waste Hg Analysis M-7600.pdf (teledyneleemanlabs.com)

There are three easy steps for changing the dynamic ranges. So, what affects the dynamic range of a continuous flow system?

First, the gas flow: high flows equal short residence times and speedy results, decreasing sensitivity. Low flows equal long residence times but increased sample times and increasing sensitivity.

Next is the pump rate. This will increase or decreases time to GLS and Hg load or the amount of mercury atoms in each amount of sample loaded into the continuous flow system.

And finally, the time in sample also increases or decreases the sample load. This portion of the equation can be adjusted for a steady state of the signal plateau with peak height. On the flip side, the “time in sample” can be shorter if one uses peak area; therefore, a steady state is not needed due to a measurement that is everything under the peak.

Adjust all three settings to achieve desired results to coincide with the cost saving advantages of our NEW TUBING HARNESS.

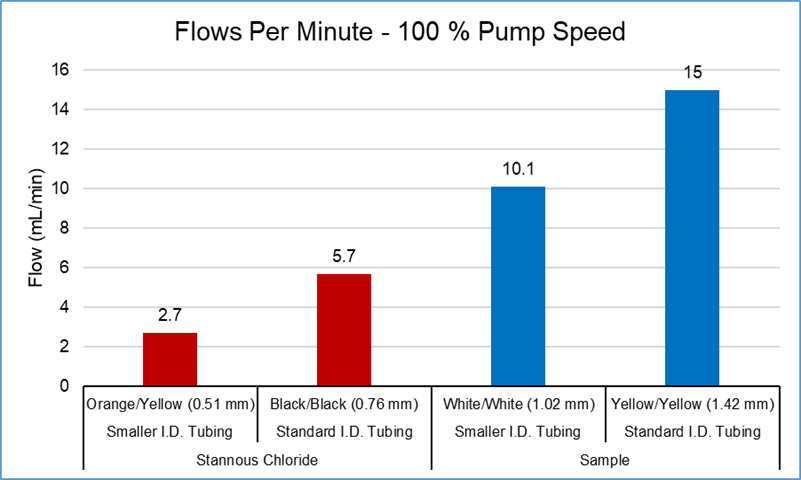

Alternate Tubing Harness “Reduced Flows,” at 100 percent pump rate the sample is ~ 10 mL/min, which is a 33 percent reduction in flow when compared to the standard tubing. The reagent flow is ~ 2.7 mL/min, which is a 53 percent reduction in flow when compared to the standard tubing. The Alternate Tubing Harness “Reduced Flows” is linear across all pump rates, and the waste generated is 60 percent of the standard tubing, so you save all around without compromising performance.

Now, here’s the big savings: stannous chloride can be expensive, but depending on your vendor rate, a laboratory can save tens of thousands of dollars. For example, at 100 percent pump rate, our Standard Tubing consumes 2.74 L /8 hours, and the Reduced Tubing consumes 1.29 L /8 hours. We recommend a 10 percent stannous chloride solution, so a 500 g bottle of stannous would be consumed by 5 L of solution. If your lab purchases stannous chloride at $450 per 500 g, the reduction in stannous chloride consumed is a savings of $130.50 for an 8-hour day, or $33,930/year in stannous chloride costs. WOW, that’s a lot of pocket change!

Figure 1: Sample and Stannous Chloride Pumping Volumes

Two methods were used to validate the reduced flows tubing harness, USEPA, 7471B (Solid Waste Manual, SW 846) and USFDA, EAM 4.5 (Elemental Analysis Manual).

Chart 1: 7471B Parameters

| 7471B Operating Parameters | |

| Sample Uptake (sec) | 35 |

| Rinse Time (sec) | 80 |

| Gas Flow (mL/min) | 100 |

| Pump Speed (%) | 50 |

| Replicate Read Time (sec) | 1.5 |

| Replicates | 4 |

Chart 2: EAM 4.5 Parameters

| EAN 4.5 Operating Parameters | |

| Sample Uptake (sec) | 30 |

| Rinse Time (sec) | 6 |

| Gas Flow (mL/min) | 125 |

| Pump Speed (%) | 80 |

| Replicate Read Time (sec) | 1 |

| Replicates | 3 |

The 35s sample uptake resulted in sample flow for USEPA 7471B at ~ 3mL (5 mL/min) pumping rate (50 percent) with a stannous chloride consumption of only 2.6 mL/sample. The total combined waste was ~ 12.2 mL/sample, which includes stannous chloride, sample, and rinse solution.

At 30s of sample uptake with 80 percent pump rate (8 mL/min), USFDA EAM 4.5 consumed ~ 4 mL of sample and 3.74 mL of stannous chloride. The total waste generated to include the rinse solution was ~ 16.4 mL/sample.

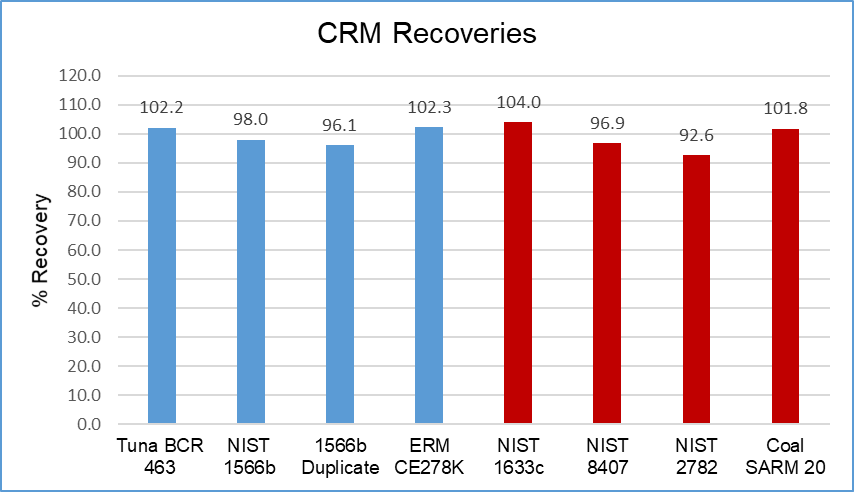

A broad array of reference material was chosen for the validation process and all recoveries where well within an acceptable range. See figure 2.

Figure 2: CRM Recoveries (Blue = USFDA EAM 4.5 results, Red = USEPA 7471B Results)

For more information on how you can save on your stannous chloride consumption with your Teledyne Leeman Labs QuickTrace® M-7600 CVAA mercury analyzer, visit our resource center at teledyneleemanlabs.com or click the link below to review our application and technical notes on using this “Green Chemistry” pump tubing harness.

Green Chemistry: Decreased Reagent Consumption and Waste Using

Reduced ID Tubing on the QuickTrace® M-7600 CVAA Mercury Analyzer