This is part 2 of the Inductively Coupled Plasma Optical Emission Spectrometry series. Part 1 described what ICP-OES is and how it works. Part 2 will be an overview and cover some of the components.

This is part 2 of the Inductively Coupled Plasma Optical Emission Spectrometry series. Part 1 described what ICP-OES is and how it works. Part 2 will be an overview and cover some of the components.

Overview

Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES) is a multi-element, trace-analysis technique used to measure the concentration of various elements in a variety of sample matrices. Also known as Inductively Coupled Plasma Atomic Emission Spectroscopy (ICP-AES), the technique is capable of measuring the majority of the elements in the Periodic Table and is currently one of the most widely used methods for elemental analysis today.

The basics of the ICP-OES technique are simple. ICP-OES uses an extremely high-temperature argon plasma to excite atoms such that they emit their characteristic wavelengths of light (emission lines). The intensity of the emitted light is directly proportional to the concentration of the elements in the sample. By measuring the emitted light by known and varying concentrations of an element (by what’s known as “calibration”), the concentration of an unknown sample can be determined by comparison.

Depending on the type of samples to be analyzed and the elements to be determined, an ICP-OES system can be configured in one of three configurations to optimize analysis: radial, axial and dual-view.

Interested in more information on ICP-OES? Contact us

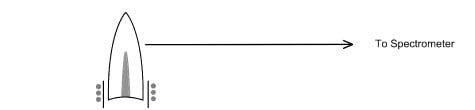

Radial View Plasma Configuration

The radial (or side-on) viewed plasma is the original ICP-OES configuration and was the only view available until the mid-1990s. This view established ICP as a dominant trace-element analytical technique, and has the ability to measure both very high and very low concentrations of elements in samples (known as “dynamic range”). This design is also capable of handling samples with high levels of dissolved solids, and is remarkably free of chemical interferences and easily ionized element (EIE) effects.

Typical sample types suited for analysis using the radial view are wear metals in oils, wastewater and industrial material such as fertilizers and brines.

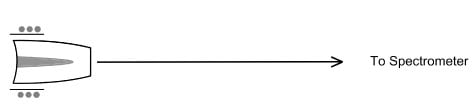

Axial View Plasma Configuration

Axial (or end-on) viewed plasma improves on the sensitivity and detection limits of the radial view by a factor of 10 or more, depending on the element. This is accomplished by looking down, through the plasma, rather than across it (as in the radial view). The dynamic range is unchanged, but is shifted towards the lower concentrations. Use of the axial viewed plasma is limited to clean sample matrices.

Typical sample types suited for analysis using the axial view are drinking water, soils and pharmaceutical materials.

The improvements in sensitivity and detection limits are not without drawbacks. Axially viewed plasma is much more susceptible to interferences, especially when analyzing samples containing high levels of dissolved solids. Additional interferences are encountered when alkali elements (Li, Na and K) are measured. Results can be wildly inaccurate, unless special precautions and sample pretreatments are performed. These types of interferences are known as the Easily Ionized Element (EIE) effect.

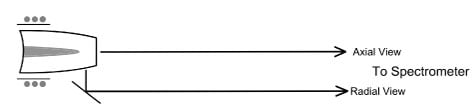

Dual (Axial and Radial) View Plasma Configuration

A dual-view ICP is capable of viewing the plasma in both the axial and radial orientations, and is an axial configuration with the addition of a mirror to observe the plasma from the side. Many radial view plasmas also use a mirror.

The advantage of the dual-view system is that it combines the best features of the radial and axial views in one instrument: the dynamic range and freedom from interferences of the radial view and the improved sensitivity and detection limits of the axial view.

Typical sample types suited for analysis using dual view are wastewaters, soils and fertilizers.

Sample Introduction System

An ICP-OES sample introduction system consists of a peristaltic pump, nebulizer and a spray chamber. The purpose of the sample introduction system is to convert the liquid sample into an aerosol that is more easily introduced to the sample injector tube in the torch, and in turn into the plasma itself.

The peristaltic pump is used to provide a steady flow of solution to the nebulizer. By changing the speed of the pump and/or the diameter of the peristaltic pump tubing, the amount of sample being presented to the nebulizer can be varied. Depending on the sample matrix, different types of tubing materials are available to handle aqueous and organic sample types.

Nebulizer

The function of the nebulizer is to convert the sample solution to an aerosol. By far the most common design used for ICP-OES is the pneumatic nebulizer, which uses the mechanical forces of a gas to break up the liquid into an aerosol (similar to the way an aerosol spray can works). Some of the most popular designs of pneumatic nebulizer include the concentric, crossflow, Babington, v-groove and Hildebrand grid nebulizers. They are usually made from glass but polymers and plastics are becoming increasingly popular, particularly for samples that are highly corrosive. Other aerosol generation devices such as ultrasonic nebulizers and hydride generators have been proven to be useful for some specific applications. The aerosol generated by the nebulizer is then passed through the spray chamber.

Spray Chamber

The function of the spray chamber is to first reject larger aerosol droplets and secondly smooth nebulization pulses produced by the peristaltic pump. Generally speaking, there are two designs used in today’s commercial ICP-OES instrumentation: the cyclonic and the double-pass spray chamber. The double-pass was initially the most common type used when ICP-OES was first commercialized, but has since been replaced in popularity by the cyclonic design for most applications.

Cyclonic spray chambers operate by centrifugal force. Droplets are discriminated according to their size by means of a vortex produced by the tangential flow of the sample aerosol and argon gas inside the chamber. Smaller droplets are carried with the gas stream into the plasma, while the larger droplets impinge on the walls and fall out through the drain. It is generally accepted that a cyclonic spray chamber has a higher sampling efficiency. This translates to higher sensitivity and lower detection limits when used for the analysis of clean sample matrices.

The Scott double-pass spray chamber design selects the small droplets by directing the aerosol into a central tube. The larger droplets emerge from the tube and exit the spray chamber by gravitational force, through a drain tube. After the sample aerosol passes through the spray chamber, it is forced through the sample injector tube inside the torch, by the nebulizer gas pressure.

Plasma Torch, Spectrometer and Detector

Once the aerosol reaches the plasma it is desolvated, vaporized and atomized. The energy of the plasma causes atoms and ions to emit their characteristic wavelengths of light. Using a system of finely tuned optics, the image of the plasma (containing the sample’s wavelength emission line and light intensity information) is directed to the optical spectrometer.

In the spectrometer, individual emission lines are separated from each other using a series of focusing optical components and a high-resolution dispersion grating. Finally, the detector converts these emission lines from light energy into electrical energy. The electrical energy is then used to quantitate the elements present in the sample and their respective concentrations.

Prodigy 7 ICP -OES

The Prodigy7 Inductively Coupled Plasma (ICP-OES) provides superior analytical performance and has distinct advantages over other ICPs. Available in radial, axial and dual-view configurations for your sample type and concentration range.

The Prodigy7 Inductively Coupled Plasma (ICP-OES) provides superior analytical performance and has distinct advantages over other ICPs. Available in radial, axial and dual-view configurations for your sample type and concentration range.

- Large-format, advanced CMOS array detector, the largest, most technologically advanced array detector available today. High-speed CMOS technology shortens sample analysis times and improves linearity.

- Full wavelength coverage from 165 - 1100 nm

- 800 mm Focal length, low stray light optics

- Full Spectral Access (FSA) captures the entire wavelength spectrum in a single reading

- Twist-n-lock sample introduction system delivers perfect torch positioning every time and improves day-to-day reproducibility

- Demountable, low-flow torches reduce argon consumption and consumable cost

- 4-Channel peristaltic pump provides the flexibility required for hydride generation and on-line addition of internal standards

- Simple to use software with built-in scheduled maintenance monitor

- Designed, engineered and manufactured in the USA

Prodigy Plus

The Prodigy Plus Inductively Coupled Plasma (ICP-OES) provides superb resolution, stability and detection limits for reliable results, with a wide variety of optional features. Available in radial, axial and dual-view configurations for your sample type and concentration range.

The Prodigy Plus Inductively Coupled Plasma (ICP-OES) provides superb resolution, stability and detection limits for reliable results, with a wide variety of optional features. Available in radial, axial and dual-view configurations for your sample type and concentration range.

- Large-format, advanced CMOS array detector, the largest, most technologically advanced array detector available today. High-speed CMOS technology shortens sample analysis times and improves linearity.

- Full wavelength coverage from 165 - 1100 nm (135 - 1100 nm with halogen option)

- 800 mm Focal length, low stray light optics

- Full Frame (FF) imaging captures the entire ICP spectrum at once

- Twist-n-lock sample introduction system delivers perfect torch positioning every time and improves day-to-day reproducibility

- Application specific sample introduction systems

- 4-Channel peristaltic pump provides the flexibility required for hydride generation and on-line addition of internal standards

- Simple to use software with built-in scheduled maintenance monitor

- Fast system startup and reduced gas consumption

- Designed, engineered and manufactured in the USA

Interested in more information on ICP-OES? Contact us today